Alexander BAKAEV

Ph.D., deputy director of the Fuels and Energy of the Technology Development Institute

e-mail: info@irttek.ru

Dmitry KOPTEV

Media relations director of the Fuels and Energy Technology Development Institute

e-mail: info@irttek.ru

Introduction

Oil and petroleum products (especially fuel) are of great interest to criminals all over the world. These products themselves are quite difficult to identify by belonging to a specific manufacturer, so the trade in stolen or falsified fuel from stolen raw materials remains a highly profitable and not too risky business. As a result, manufacturers and transport companies suffer billions of USD annually, the state budget does not receive duties worth hundreds of millions of RUR, and consumers receive gasoline and diesel, which damage engines and harm people and the environment.

Today, there are technologies that allow solving this problem and a number of other equally pressing issues of the oil and fuel markets. We are talking about the labelling of oil and oil products, which is widely used in different countries.

In March, Transneft announced two tenders for the development of technologies for labelling oil and oil products. According to the results of the competition, in the period from the end of May 2021 to the end of January 2022, studies of the influence of the marker on the quality of oil and oil products, on the processes of transportation and oil refining should be performed.

The main goal of research and development is to enhance the efficiency of control over the quality of oil and petroleum products when receiving from shippers, transportation and delivery to consignees in the Transneft system, excluding theft and re-delivery and replacement for raw materials and products of inferior quality [1].

We will try to find out how technologies for labelling oil and petroleum products are applied in world markets, whether this gives tangible advantages to national markets and economies, sellers and consumers, whether there are restrictions on their use, what are the prospects for the development of labelling technologies.

Goals and objectives of labelling oil and oil products

The fuel labelling system [2] is a comprehensive program employing the advanced authentication technology consisting of secure molecular markers, networks of mobile and central laboratory control analysers, accurate and rapid testing methods, and an advanced information management system that generates timely and actionable information. allowing governments to reduce the risks of tax evasion and abuse of budget subsidies, minimize financial losses and increase tax collection.

Purposes of labelling [3]:

- Combating fuel counterfeiting and illegal trade in substandard products.

- Ensuring the collection of taxes and fuel excise taxes.

- Quality assurance for all types of fuel, increasing consumer confidence.

- Ensuring the operability of vehicles, heating equipment by ensuring the proper quality of fuel.

- Prevention of illegal import of petroleum products and dumping due to transit, export or subsidized fuels.

- Brand protection.

- Environmental Protection.

The topic of labelling everything and everyone (from machine parts to dairy products) has become firmly established in business and everyday life.

Over the past decade, there has been an ever-increasing flow of publications on this topic, the total number of publications in the Russian-speaking space has exceeded 700 thousand.

It is argued that the labelling of goods allows to bring quality control to a fundamentally new level, eliminate counterfeiting, facilitate the fight against smuggling, civilize markets, etc.

A new context for the application of labelling technologies has arisen and is developing in the context of sanctions and trade confrontations.

The use of fuel tinting was actively discussed in the early 1980s to counteract the theft of state gasoline, in the image and likeness of some countries of the socialist camp (Hungary, the GDR), but such procedures were never introduced into the all-Union practice.

Most countries are prone to fuel fraud, but in case of developing countries that count every penny in their budgets, labelling technology can add significantly to their budgets.

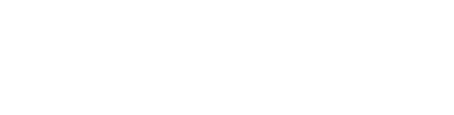

Colour markers are used at refineries to control the quality of the released fuel consignments (schematically shown in Fig. 1).

To date, fuel labelling technologies, which have been actively developing within the state programs in the developed countries’ markets, are also used in the fuel markets of the “third world” countries.

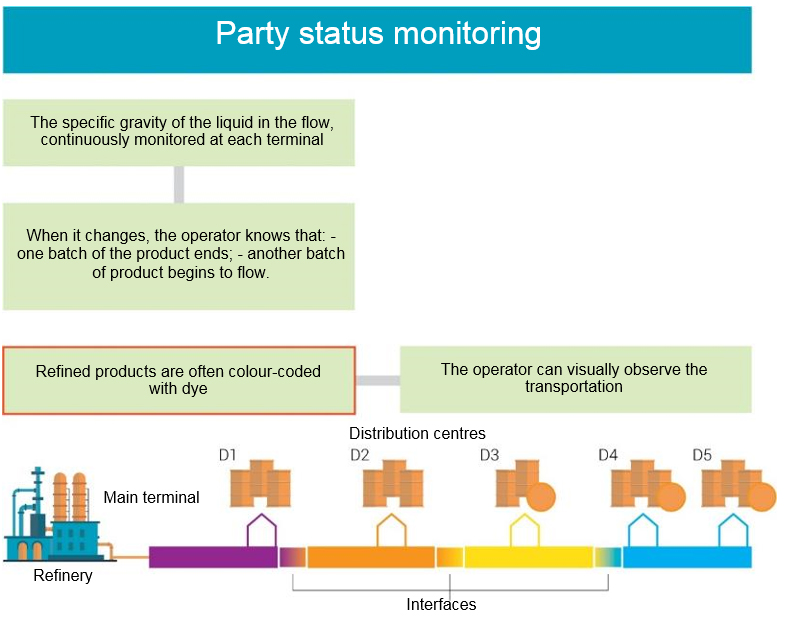

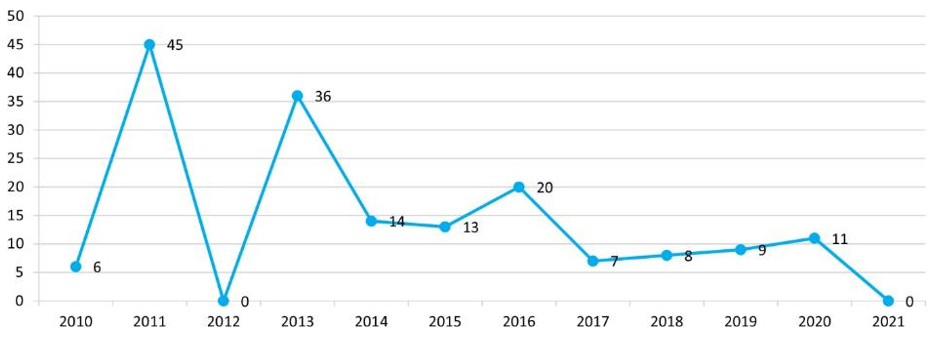

In Russia, such technologies have not yet widespread noticeably, as evidenced by thematic media activity (see Fig. 2 and Fig. 3):

there are few reports on the labelling of oil and petroleum products in the media (in comparison with the array of messages and labelling of other goods).

Period 01.01.2010 – 22.04.2021

Source: SCAN-IF data

Source: SCAN-IF data

The Rospatent repository contains several patents for inventions related to the labelling of oil and oil products. In scientific magazines, based on the data of the Elibrary scientific electronic library, only a few articles on the development and application of marker technologies have been published, mainly affecting the topic of labelling other products.

Technologies applied in the labelling of oil and oil products

One of the technologies used in fuel labelling to prevent smuggling is X-ray fluorescence (XRF). This solution triggers a reaction in certain fuel molecules as it passes through the detector, generating certain pigments in it that indicate the origin of the fuel.

X-ray detectors are so specific that they also detect sulphur levels in fuel, in addition to monitoring the presence of wear metals in lubricants to prevent engine wear.

The gas chromatography method consists in analysing the gases released by the fuel when their temperature rises, thus, it is possible to determine such additives as bromine, chlorine or fluorine, which are introduced into gasoline and which are not contained in the original composition of the fuel.

Chromatography has been combined with mass spectrometry to provide more specific molecular measurements of the substances comprising gasoline. The combination of both technologies allows formulations to be separated based on their properties, and to measure the specific fingerprint of the marker.

This mechanism has been used for fuel marker analysis for over 20 years, primarily as a laboratory process supporting the development of fuel integrity programs, but field diagnostic tools have been developed and upgraded.

The most common markers are dyes, which are molecules injected into gasoline that, when other solvents are added, cause a chemical reaction that changes the fuel colour of the fuel.

Further, by the well-known colour characteristics, one can find out whether the fuel has been diluted with other substances, including those of dubious origin.

The technology of DNA markers [4], which are unique combinations of nucleotides with inserted fluorophores that cannot be copied or duplicated, also appeared in the 2000s.

Modern technologies allow develop an individual marker composition for the client, considering the characteristics of the product. At its discretion, the manufacturer can store information about the labelled product in an international databank, which, in turn, will allow determining the place and date of production of a batch of petroleum products, belonging to a specific manufacturer, destination and other data.

In 2016, the media often mentioned the development of researchers from the Department of Physical Chemistry and Chromatography of Samara University – technology of hidden labelling of oil. The method is based on the addition of molecular markers to oil, which will allow determine the location of production and the route of oil transportation. These markers are not poisonous, non-toxic, are not catalytic poisons, and are completely decomposed during oil refining. Using the method of gas chromatographic analysis, these markers will allow find out where the oil was produced, when it was shipped to the consumer; if there is a set of necessary control points, it is possible to track its route to the place of processing, and then, using other sets of markers, track the path of oil products to consumers.

Of greatest interest is the patent for the invention “Method and system for labelling and identifying the authenticity of liquid hydrocarbons”, the copyright holder of which is the Atomic Energy Commission of Israel.

This invention allows to identify oil, gasoline, kerosene, various types of fuel to assess the preservation of the original quality (dilution, counterfeiting), spill or leakage of liquid hydrocarbons from pipelines, tankers or storage facilities. However, the claims are drawn up in a rather generalized manner.

Source: Transneft

Proposed solutions for labelling oil and petroleum products

According to the Swiss company SICPA, a molecular marker is the most efficient technology for tracking the theft and tampering of fuel [5].

The molecular marker is only required in very small quantities and can be automatically injected into the fuel. Reliable and indelible markers are used; they do not change the characteristics of the fuel and are extremely stable for a long time, do not harm the environment and do not affect the functioning of vehicles.

Herewith, minimum differences in concentration can be detected. The technology has been applied in developing countries such as the Philippines, Mozambique, Albania, Uganda and Tanzania as part of efforts to eradicate illegal fuel markets. In these countries, gasoline fraud has been eradicated through the correct application of sophisticated molecular labelling solutions and other legal and regulatory measures.

The same company offers mobile analysers for the control of marked fuel, as well as a machine learning system that can significantly enhance the efficiency of control.

The fuel labelling system (including biofuels) and other goods using DNA technologies (CypherMark™ product) and luminescent technologies (ValiMark™ product) is used by TraceTag International (UK – Norway) [6].

In Russia, solutions based on DNA markers from TTI are offered by DISPAK [7].

It is argued that DNA markers cannot be copied or duplicated and that the results of its application serve as 100% proof of the identity of hydrocarbons and petroleum products in courts. The DNA tags are determined by mobile analytical complexes based on the method of polymerase chain reaction (PCR).

CNITI “Tekhnomash” proposes the development of methods and means for labelling petroleum products and crude oil [8].

The identification of oil and oil products is supposed to be performed on the basis of the implementation of a specific marker substance and luminescent readout using an inexpensive, compact, wearable device that does not require high qualifications of service personnel.

The approximate time of the complete analysis cycle from the moment of sampling to obtaining the result is 20-30 min. The method provides for the simple sample preparation requiring no special chemical skills and education.

The reading device weighs about 500 g and is powered by standard batteries.

Source: EP

Tracerco (Great Britain), along with services and oil production controls, offers its own fuel labelling technologies (environmentally friendly markers of carbon, hydrogen, oxygen and nitrogen (CHON)); provides governments and brand owners with tailor-made programs to protect the fuel supply chain from dilution, replacement and smuggling [9].

The basis is the Company’s own markers, portable analysers, laboratory analysis services, visualisation of test results using the Tracerco™ Insights cloud platform.

Tracerco’s national fuel labelling programs have returned more than USD 10 bln to customers, the company claims. The programs are aimed at the following:

- Increase fuel tax revenue and recover additional revenue lost from fuel fraud.

- Fight against smuggling, falsification, abuse of discounts and substitution of fuel classes.

- Identifying fraud nodes in supply chains.

- Obtaining evidence to support a prosecution or other action against illegal criminal activity.

- Reducing public health and environmental risks by reducing fuel emissions associated with the use of counterfeit fuels.

- Enhanced fuel quality leading to fewer vehicle and plant breakdowns.

- Demonstration of good governance to international organisations and financial institutions such as the IMF and WB.

In the case of the production of petroleum products, as well as their transportation by tankers or multi-product pipelines, all these quality control technologies work and bring, judging by the reports of companies and government agencies, considerable benefits.

However, labelling crude oil in trunk pipelines is more challenging. The Urals blend is supplied to consumers and one can recall the statements of some oil producers that their oil is of higher quality in comparison with the blend, but is sold at the Urals price.

Accordingly, the main control shall be at the entrance of each supplier into the pipe.

At the inputs, markers are launched with a certain speed and density – each supplier has its own marker with a density proportional to the pumped volume.

There is a mixing, including markers, but the signs are not lost and the number of markers remains constant for each batch of oil (although all this is distributed over some distances during the operation of the pumps, that is, it is required to raise the hydrodynamic models and try to estimate the temporal and spatial distributions markers along the pipeline). At the control points and at the exit, markers are registered, recognized, the density of each

is estimated and a picture is built; as a result, it will be possible to draw conclusions about the invariability of the composition of the liquid or about unauthorized pumping of liquid on some section of the line.

Most likely, this requires strict control at the entrance, including with labelling (each supplier is assigned its own permanent marker), as well as total control along the entire length of the highway using drone patrolling, space and air remote sensing and processing in real time of all data by neural networks.

Complex solutions for quality assurance are being developed pursuant to approximately the following scheme, developed by stable legal systems of developed countries:

- Determination of the quality of fuel (or raw materials) at the input.

- Fuel condition monitoring at every stage of the chain (well, storage, transport, refinery, product storage, transportation, distribution networks, etc., up to retail).

- Implementation of quality assurance methods and tools at every stage of the process, which requires labelling and marker analysis systems.

One set of markers is used to quickly solve quality control problems.

For complex programs, the next level of control is built up by adding an additional molecular marker determined by gas chromatography and mass spectrometry methods, as an option – PCR methods in the case of using DNA markers. If irregularities are detected during the measurements, suspicious samples are delivered to the laboratory for an in-depth examination.

Source: narfu.ru

Organisational and legal aspects of oil and oil products labelling

A number of countries are currently implementing various programs to counteract national fuel theft, abuse of fuel subsidies, oil spills and tax evasion.

It is believed that the volume of criminal transactions with fuel can be significantly reduced precisely through the use of national programs to ensure the authenticity of fuel.

For example, Authentix, which was formed from the merger of two leading players in the authentication industry – Isotag (USA) and Biocode (UK) – has implemented 22 national fuel labelling programs over the past 15 years. Authentix solutions are currently used by nine leading oil and gas companies in the USA, Europe, Africa and the Middle East.

Authentix technologies allow you to see fuel quality discrepancies and perform field checks, as well as laboratory testing and confirmatory analyses.

One interesting example from Authentix’s experience was working with a major oil company that acquired a petrol station network of another fuel seller, which increased its assets to more than 10,000 retail outlets in the USA. After the acquisition, the problem arose of mixing fuels of different qualities in a combined

supply chain. There were also concerns about a shortage of gasoline at fuel terminals on the network, which gave wholesalers the ability to fill unmarked fuel into trucks [10].

To solve the problem, Authentix applied a comprehensive fuel authentication methodology using core technologies. These included mass differentiated markers and gas chromatography – mass spectrometry (GC/MS), which is considered the gold standard in forensic science. As a result, the number of failures decreased by 7%. The implemented solution also led to increased revenues by reducing the time to replace non-branded products.

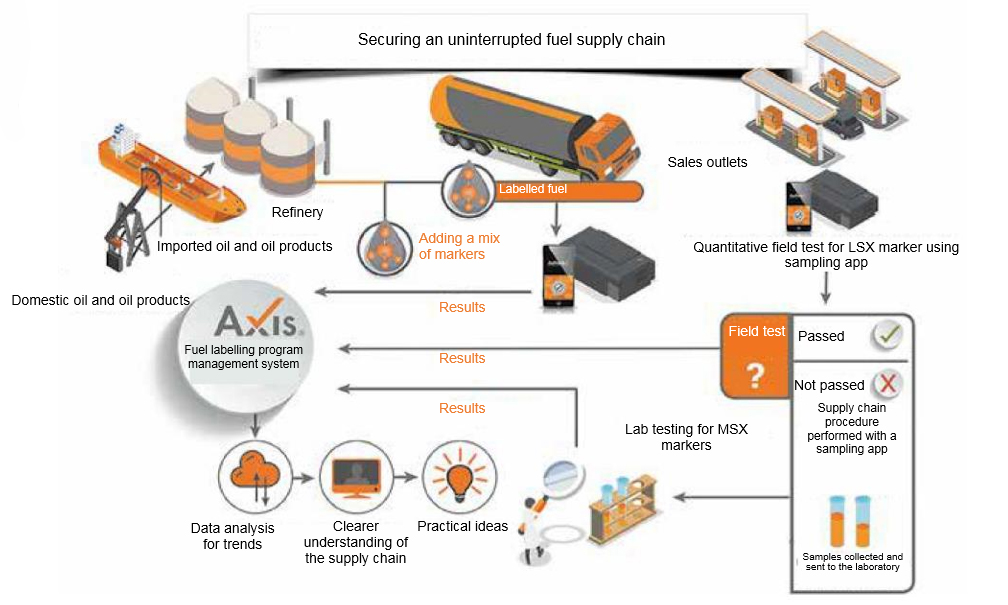

The integration of fuel labelling and quality control processes into the supply chain used by Authentix is shown in Fig. 4 [11].

As we can see from the diagram, the labelling is added to the fuel at the stage of oil refining and then tested both at the stages of transportation and directly at the filling station. If any of the samples fails testing, it is sent to the Authentix laboratory for more detailed examination. The collected data is accumulated in the Axis system, which allows to analyse the operation of the system as a whole and make the necessary adjustments to it.

Cotecna also collects fuel test results on a single intelligent platform. The innovative testing method used by the company gives results in just a few minutes and allows not only to quickly identify fuel that has been tampered with or came from illegal sources, but also enables customers to quickly obtain the necessary information [12].

The standards used in the labelling of oil and petroleum products are currently most developed in the United States, where there are a large number of organisations dealing with these issues.

The oil and gas sector applies standards from the American Petroleum Institute (API), American National Standards Institute (ANSI), American Society of Mechanical Engineers (ASME) and the International Organisation for Standardisation (ISO).

For example, the American company Automator operates in accordance with the standards and requirements of the American Petroleum Institute (API).

Automator designs, manufactures and provides solutions for creating environmental resistant labelling on drilling tools, sensors and other equipment.

For engine oils, the international quality standards API, ACEA, ILSAC and ААЕ, developed by large expert organisations, are applied. Engine oils are also independently tested by the Petroleum Quality Institute (PQIA).

Information about the standards for labelling oil and oil products is extremely scarce due to the fact that such labelling must be reliably protected from any possible counterfeiting. Therefore, labelling companies in their information materials are limited to common places in the description of technologies, methods and standards.

Labelling and benefits of oil and petroleum products

Ernst & Young estimates that the annual volume of illegal fuel trade is USD 133 bln a year, and this amount continues to grow [13]. According to other estimates, this figure exceeds USD 150 bln a year. This includes direct losses to the budgets of countries, manufacturers and brand owners, as well as funds raised by criminal gangs in the course of marketing the counterfeit, stolen and low-quality products.

In Russia, the use of low-quality fuel, especially for agricultural machinery (i.e. heating oil instead of diesel fuel) is developed. In predominantly agricultural regions, at gas stations, a mixture of heating oil with a share of diesel is sold as unclassified diesel, naturally at reduced prices. In this case, along with the additional burden on the environment, we also get the risk of vehicle breakdown, which, possibly, leads to an increase in road accidents as well.

Fuel labelling programs have been proven to recoup lost revenue to governments and brand owners and help secure future supply chains.

Many developing countries faced with problems in fuel supply chains – such as smuggling, counterfeiting and dilution of fuel, outright theft, etc., have developed and are implementing government fuel labelling programs. An example is the program of the Philippines, whose budget was losing at least USD 750 mln annually due to the smuggling of fuel from neighbouring countries with subsidized fuel [14].

The press described, for example, such “arbitration” schemes [15].

Tank trucks from the UAE, where diesel fuel cost 15 (!) times cheaper than in Saudi Arabia, were loaded at KSA enterprises with used mineral oils and diesel fuel in a ratio of about 1:7, and the documentation was issued for a full batch of oil; then, in the UAE, diesel fuel was separated from oil and fed to sales networks.

Similar schemes worked between Venezuela and neighbouring countries, albeit before the intensification of the crisis in the economy of the Bolivarian Republic.

Fuel fraud also causes irreparable damage to the environment – low-quality fuel, impurities and by-products (residues of the same waste oil) lead to increased fuel consumption, increased greenhouse gas emissions, pollution of soils and water bodies with waste disposal, which leads to additional stress on ecosystems [16].

Moreover, low-quality fuel shortens the service life of vehicles and increases their maintenance costs.

One can also note the program to counteract fuel theft launched in 2016 by the Mexican company Pemex: marker technology was implemented at 360 filling stations of its network and the results showed that 148 stations were not analysed and were suspected of receiving fuel of questionable provenance.

Source: autofed.ru

Fuel labelling also helps fight corruption. In addition to its devastating impact on the quality of public services and the efficiency of justice, corruption also negatively affects legal business. Companies and people with an established reputation cannot compete with dishonest players, so the market is formed by those who are ready to ignore the laws. As a result, the economy suffers from a lack of investment, which ultimately contributes to poverty, environmental pollution and poor health for most people.

Fuel labelling allows to learn where and when counterfeit fuel entered the supply chain or to identify undeclared supply volumes. Without labelling, the legality of fuel can be checked only by tracing the document flow, which is not immune from counterfeiting and the influence of corruption mechanisms. By adding a marker to fuel, governments are able to operate with a consistent indicator of the legality of a given product.

Testing for the presence or absence of this marker provides scientific and judicial evidence of illegal activity, making it very difficult for even corrupt government officials to ignore fuel tampering, smuggling, counterfeiting and substituting low-grade fuel for high-grade fuels.

Another benefit of the fuel labelling program is its positive impact on reducing tolerance for corruption. This is often overlooked. As the fuel labelling program increases the risks of detection and increases the inevitability of legal punishment for criminals, it helps to exclude them from the market, leaving the field free for those who are willing to do business openly and honestly. Thus, a general sense of justice is enhanced as citizens know that perpetrators will not escape legal retribution. This provides added assurance that ethical business conduct will be beneficial, and as a result, the vicious circle of corruption, at least in this industry, can be broken.

Oil smuggling is global in nature, financial losses from it are significant and amount to tens of billions of USD annually.

Fuel subsidizing states suffer losses due to the fact that their fuel is illegally exported at low prices to other countries with predominantly world prices. For example, countries with fuel subsidies such as Bangladesh, Indonesia and Malaysia are particularly vulnerable to financial losses due to relatively low domestic diesel fuel prices. Fuel that is cheaper due to subsidies is smuggled out of these countries to other countries (for instance, the Philippines), where prices are close to world prices. Thus, governments are deprived of the benefits of fuel subsidy programs, while also receiving an increase in social tensions among the households for which the subsidy programs were introduced.

Counterfeiting of petroleum products is one area that causes a lot of problems for both consumers and governments. Unscrupulous businessmen mix kerosene oil with gasoline and a high-octane blend (HOBC) and sell this La Melange Infernal as the motor fuel. Kerosene is generally tax-free compared to nearly 40-50% taxes on other petroleum products such as gasoline, diesel fuel (HSD) and HOBC.

In India, the Ministry of Petroleum and Natural Gas is trying to cope with this problem, trying to launch a fuel labelling program to reduce the threat of tampering, and as a first step plans to introduce a “fuel marker” into locally produced kerosene [17].

One way to counteract theft is molecular labelling of fuel. “Molecular fuel labelling is the process of applying a unique chemical marker to petroleum products that, using high precision, allows companies and government officials to identify the fuel and detect any tampering or confusion. It facilitates the struggle against many types of

criminal activity. For example, tax evasion markers can be used to identify fuel that is subsidized or exempt from certain taxes, or to show that taxes were paid correctly”, explains Erik Besson, vice chairman of the Swiss anti-fraud company SICPA.

Similar technologies have been applied in various countries of the world with significant results. For example, Ghana applies indicators to more than 3 bln litres of fuel each year, which has enabled it to cut gasoline smuggling by 78%, reducing losses by USD 10 mln annually as of 2013. According to industry and government figures, Serbia has cut sales of questionable fuels by 75 percent as of 2014, and Colombia has almost completely solved the problem of theft of petroleum products.

Source: voanews.com

The consumer cannot determine the fact of tampering or dilution; therefore, it becomes necessary to use advanced technologies such as fuel labelling to counteract illegal trade and theft throughout the supply chain (manufacturers, transport, storage facilities, distributors, gas stations).

Marker technologies have been shown to be efficient in counteracting illegal trade; it is important to note that they are also intended not only to confirm the legal origin of the fuel, but are also used in several countries in Europe and the USA as a “quality mark”, since markers allow detecting any changes in the product, as well as mixing it with a product of another brand, which is the basis of several brand protection programs.

The design of control systems, detection and/or application of markers is not an easy task. Choosing the right molecule implies that the company or group of companies meets to determine the scope of what is being sought, the labelling company identifies the most reliable molecule for the specific characteristics of the products being labelled, and the best detection system to determine the traceability of each. droplets of marked fuel. These types of actions can be developed in conjunction with governments to achieve better results.

Such fuel labelling programs allow control and certification of all activities related to the production, transportation, storage and distribution of fuel. In the event that fraud is detected, after processing the data received, objective evidence is provided to the controlling and judicial authorities.

Conclusions

The implementation and development of technologies for labelling oil and oil products undoubtedly looks like a useful and promising step for the sustainable and civilized functioning of the industry and the market (including the EAEU market).

Not only can many problems related to counterfeiting, theft, illegal circulation of products be solved, such technologies will also help to strengthen the brands of all participants in the oil and oil products market, who have earned a high reputation of consumers and partners, and do not intend to lose it due to the illegal actions of some participants.

The development and implementation of corporate and state programs for labelling oil and oil products shall have a significant PR effect at the federal and international levels, and not only on the basis of civilizing business initiatives, but also on the basis of innovation, development and implementation of high technologies and digitalisation of business, which is positively perceived and by the public and “you-know-whom.”

Labelling programs also contribute to the development of large-scale intelligent systems for processing and analysing information, supporting management decisions; such information systems are becoming an important part of business management systems, and the quality of management already directly plays a role in improving public sentiment, returning at least part of the optimism lost during the pandemic.

Therefore, government and corporate programs to control fuel markets through the use of labelling technology are essential, and their implementation shall be performed in the near future in order to unravel the whole tangle of problems facing the industry and lay the long-term prospects for its activities as soon as possible.