Viktor ZHAICHENKO

Chief of laboratory, Joint Institute for High Temperatures of RAS, D. Eng. Sc.

e-mail: zaitch@oivtran.ru

Adolf CHERNAYVSKY

S. s. o., Joint Institute for High Temperatures of RAS, C. Eng. Sc.

e-mail: zaitch@oivtran.ru

Renewable energy sources using is associated with the need to solve problems of guaranteed energy supply to consumers. In current practice, these issues are resolved either by feeding systems with renewable energy sources from existing energy systems, or by creating duplicate autonomous sources on fossil fuels, or by using storage systems with high-capacity electricity storage devices. In this article the prospects for the renewable energy sources main types combined using with the creation of additional energy sources based on biomass are considered.

Keywords: renewable energy sources, bioenergy resources, distributed energy, biomass-to-energy conversion.

Introduction

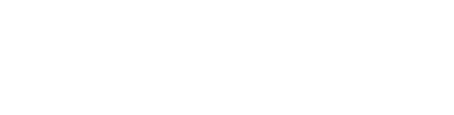

In Russia the main power supply to consumers is provided by the Unified Energy System (UES) of Russia. Fig. 1 illustrates the structure of generating capacities. The biggest volume of power supply to consumers (67%) is provided by traditional thermal energy sector, which at the same time is the biggest man-caused source of harmful emissions to atmosphere, soil, hydrosphere. efficiency of major portion of existing large steam turbine thermal power plants is 38–40%. New TPPs with combined cycle technologies have efficiency of 55–60%. That is, 40–60 % of energy of the fuel fired at a TPP is wasted into the environment in the form of heat in any case. This results in significant negative consequences for the environment.

Construction of large hydraulic power plants is associated with negative environmental impact as well. Water storage basins required to control HPP performance occupy significant areas withdrawn from agricultural use. Often these water storage basins are arranged by flooding forests and even settlements. Dams across rivers result in reduction of hydrobionts in river water areas.

NPPs are power plants causing the greatest environmental problems and public protests in Russia and all over the world. Especially after major radiation accidents at Three Mile Island NPP in the USA in 1976, at Chernobyl NPP in the USSR in 1986, at Fukushima NPP in Japan in 2011.

NPP construction is 1.5–2 times more expensive than steam turbine TPP and 2–3 times more expensive than modern TPP with combined cycle technologies [1].

The share of nuclear power generation in the global electric energy production has reduced from 17.6% in 1996 down to 10.7% in 2015 [2]. Peak of nuclear power generation was observed in 2006 (2660 TW·h). According to Bloomberg New Energy Finance, the total NPP share in the world will drop down to 4% by 2040.

Neither construction of new plants, nor reconstruction of existing large traditional TPPs, HPPs and NPPs are considered as rational in the practice of modern power sector development in the world.

At the same time, a significant growth is observed in power generating capacities using RES.

Before 2010–2012 high prices for photovoltaic modules undercut the case for wide use of solar generation. Currently, with the cost of photovoltaic modules about $300–600 per kW they become the cheapest equipment for electric power generation. According to many experts, now construction of NPPs and TPPs already becomes economically unreasonable in EU countries, in Chine and India, and in southern regions of Russia.

Carbon-neutral power industry – the main direction of development

The main direction of development of the world power system now is migration to carbon-free power industry. According to forecasts published in the global report of REN21 Center on the state of renewable generation [3], the use of brown coal will be stopped by 2035, hard coal – by 2045, oil, gas, nuclear fuel – by 2050. The trends under consideration are governed by the intention of governments of all countries to ensure competitiveness of national economies and accelerate their economic growth through access to cheaper energy, improve security of energy supply through the use of local low-carbon sources and to reduce dependence on imported hydrocarbons.

The stable economic background for widespread use of RES allows constructing new power sector in Russia as well, with lower specific investments in 1 kW of installed capacity and with cheaper electric power generation. To make this statement not seeming unsubstantiated, we provide results of comparison calculations of key parameters for traditional and non-traditional electric power plants in the existing Russian conditions (Table 1).

The basis for comparison is taken as a reference NPP with an installed capacity of 1000 MW operated in the basic mode with mean unit capacity factor (UCF) equal to 80%, which is equivalent to 7000 hours of installed capacity usage time per annum. All other generating capacities have average UCF values less than that of NPP, as can be seen in Table 1.

Calculated output of electric power from the reference NPP is 6650 TW h/year (or mln kW h/year). For adequate comparison the same calculated electric power output is assumed for all other types of electric power plants to be compared. To meet this condition under a significant difference in UCF for various generation technologies, it was necessary to take the following values of installed electric generating capacities:

- for coal-fired TPPs – 1268.4 MW;

- for natural gas-fired TPPs – 1536.7 MW;

- for HPPs – 1737.2 MW;

- for WPPs – 2283.1 MW;

- for SPPs – 3474.3 MW.

Wherein calculated investment volumes (САРЕХ) to construct the power plants in question were as follows:

- for NPPs – 371 bln rub;

- for coal-fired TPPs – 266.4 bln rub;

- for natural gas-fired TPPs – 247.4 bln rub;

- for HPPs – 364,8 bln rub;

- for WPPs – 207.8 bln rub;

- for SPPs – 206.7 bln rub.

Despite the required WPP and SPP capacities are considerably greater than those for all other types of power plants, construction of WPP and SPP requires the smallest investment in the currently formed market situation. At the same time the cost of electric power output from WPP and SPP is the lowest as well.

It is worth noting that wind and solar generation, as compared with other facilities, have considerably shorter payback periods of investments – PP (discrete payback period) and TPP (total payback period), considerably higher net profit values (NP) and net present values over the period of calculation (NV and NPV), the highest profitability index values (PI) and return on investment (ROI).

Many power generating companies came to a conclusion that economic considerations make unreasonable construction of NPPs, TPPs and large HPPs, and priority should be given to RES-based technologies. World-renowned SIEMENS company today already reduces manufacture of its gas turbines due to significant drop of demand for them.

Today construction of new TPPs and NPPs in Russia, even with improved parameters, will only enlarge arrearage of our energy sector from the world level of development. By using traditional power generating equipment we doom our country to use old energy technologies for at least next 40 years, i.e. for a period equal to service life of this equipment. But in 10-15 years an urgent need will already arise to construct substitution power plants based on RES that have (as can be seen from Table 1) considerably better parameters of cost, profitability, cost-efficiency. And constructed today traditional TPPs and NPPs with investment payback periods of 20–25 years will be non-competitive in power output to consumers. This will lead to the need to put them out of service without complete return of the investments made in their construction. Similar phenomena in EU countries already have resulted in loss of about $20 tln in the power sector [4]. And if as far back as 3–4 years these issues weren’t so sensitive, now it is inadmissible to loose time without large-scale implementation of new technologies based on RES.

Our country has significant reserves to improve energy efficiency because specific power consumption of Russian GDP is 1.5–2.5 times higher than in the USA, Japan, some EU countries. By now main directions of upgrading the existing power system in Russia are defined by the Energy Strategy of the Russian Federation [5] and the General Layout Plan of Power Facilities until 2035 [6]. Development of renewable generating is conceptually planned as well. However, activities in this part of the Strategy are defined in an unclear and unspecific manner.

That’s exactly why construction of large WPPs, SPPs, GeoTPPs, biomass-fired TPPs, small HPPs, etc. develop spontaneously in Russia, on arbitrarily chosen local areas within the country by suggestions of individual domestic and/or foreign investors – without interconnection with general program of power sector development in Russia.

It is evident that geographic (large distances), climatic (long heating season with wide fluctuations in temperature), and resource base (proximity to cheap hydrocarbon resources) features pre-define specific way for development of electric power and heat supply systems. Taking into account huge territories with low density of population, it is reasonable to develop specifically decentralized power sector [7]. The more so because up to 70% of the RF territory with a population of about 20 million people today is not covered by centralized power supply [8]. In these remote areas consumers use mainly diesel power plants of various capacity for power supply. Cost of energy at these DPPs usually is quite high – about 15–40 rub/kW h, and sometimes even greater than 100 rub/kW h [7].

Long distances and absence of centralized power supply often preclude construction of utility-scale power plants based on RES and receiving make-up from the grid to ensure guaranteed electric power supply to consumers as, for example, in EU countries. Also, it is not always possible to construct backup generating plants fired by fossil fuel: either due to difficult delivery of this fuel, or due to high prices. In these cases, the solution would seem to be the use of electric energy storage. But despite the promising results achieved in research and development of high-capacity energy storage of various types [7–8], their widespread implementation is precluded by a number of problems related to unsatisfactory specific weight/dimension parameters, complexity of control systems, insufficient stability of characteristics in time, and still high cost.

Today the use of cost-effective energy storage units increases the cost of RES-based systems by 1.5-1.8 times. It can believed that manufacture of cost-effective energy storage units requires additionally at least 5-10 years.

Solutions for the problem of creating system of guaranteed power supply.

Meanwhile an effective method of guaranteed power supply to consumers can be proposed for the Russian conditions based on RES only, i.e. without energy storage systems. This method consists in solving two main tasks: 1)the use of optimum RES combinations to ensure as uniform as possible power output during day, month, season, and all the year around with minimum need for additional power support to provide guaranteed power supply to consumers. 2)the use of biomass, which is present in one form or another everywhere over the RF territory, with its conversion to electric and heat energy to create an energy source that supplements performance of the main power facility when needed.

The main most high-potential types of RES are considered non-standard (solar and wind energy, energy of currents and waves, tides, etc.), that do not provide for sustainable power supply in time. Creating systems of guaranteed power supply based on these RES is technically possible with additional use of biomass energy, however it requires intelligent, well-justified application of various RES combinations depending on the regions in question.

Source: staff-online.ru

To minimize requirements to systems of additional energy generation from biomass, main power supply systems can be built up with the following combinations of RES types: SPP–WPP, SPP–HPP, WPP–HPP, SPP–TiPP 1*, WPP–TiPP, HPP–TiPP, SPP–WPP–HPP, SPP–

WPP–TiPP, etc., depending on types of RES available at the area planned for placement of power plants.

Biomass in Russia is the most widespread type of renewable energy sources. Our country holds about 48% of world turf reserves and 23-24% of wood reserves And it is the field of biomass energy use, where new effective technical solutions are proposed in Russia that can bring the country at the leading edge [8–13]. Novelty of these solutions is protected by a number of RF patents [14–22]. Patent holder is Joint Institute for High Temperatures of the Russian Academy of Sciences (JIHT RAS).

Potential generation of electric power from biofuel in the RF is more than 150 TW·h/year, heat energy – more than 340 GW·h/year [5].

Key features of biomass-fired power generating systems:

- presence of biomass sources everywhere in all RF regions in one form or another that are suitable for conversion to electric and heat energy;

- the possibility of long-term continuous operation in the specified capacity range if there are stocks of raw materials;

- considerably lower specific capital investments in construction of generating plants as compared with traditional options and low cost of the energy generated from biomass.

To illustrate efficiency of the proposed method of guaranteed power supply with combined use of RES, we consider as an example the project developed by Rostovteploelectroproject and JIHT RAS for non-traditional system of power supply for the Shakhty-Don Water Conduit (SDWC) in Ust-Donetsk area of Rostov region. SDWC provides water supply to the city of Shakhty by pumping water from water intake at Don river over two 33-km long pipelines with diameters of 1000 mm and 1200 mm. All pumping stations consume a power of 9500 MW in case of continuous round-the-clock operation. Payment for the electricity consumed from the grid to run the pumping stations is up to 1 bln rub per annum.

Source: Rushydro

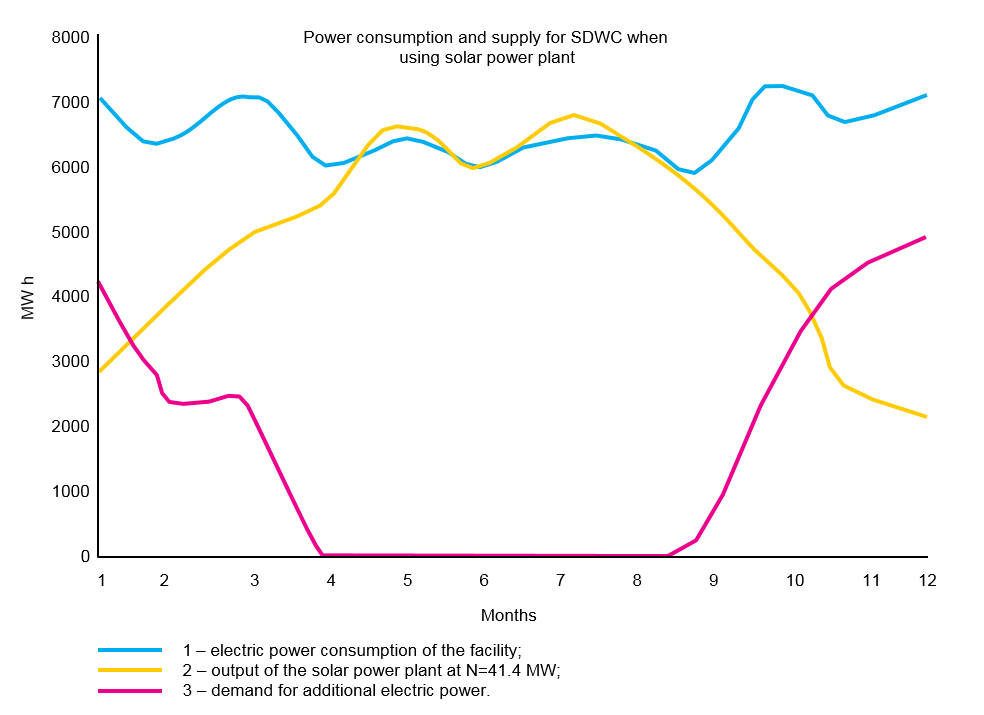

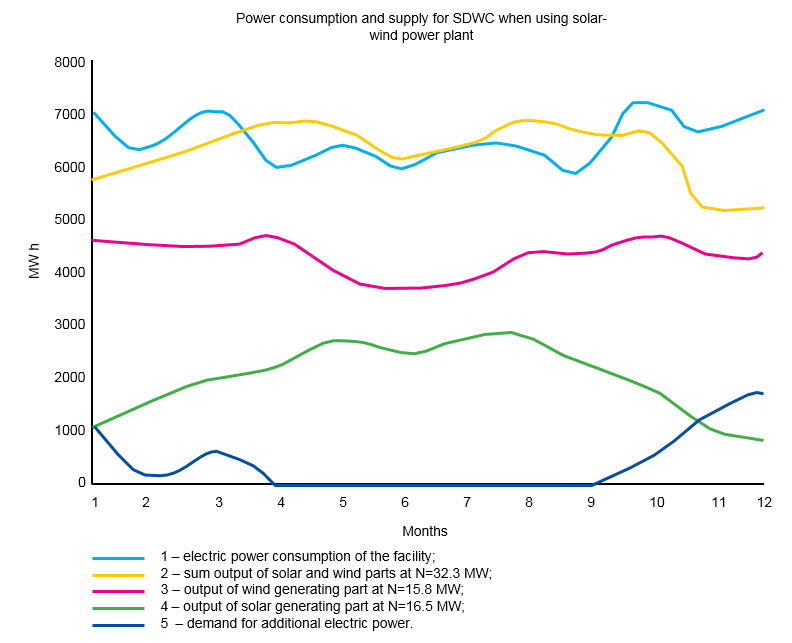

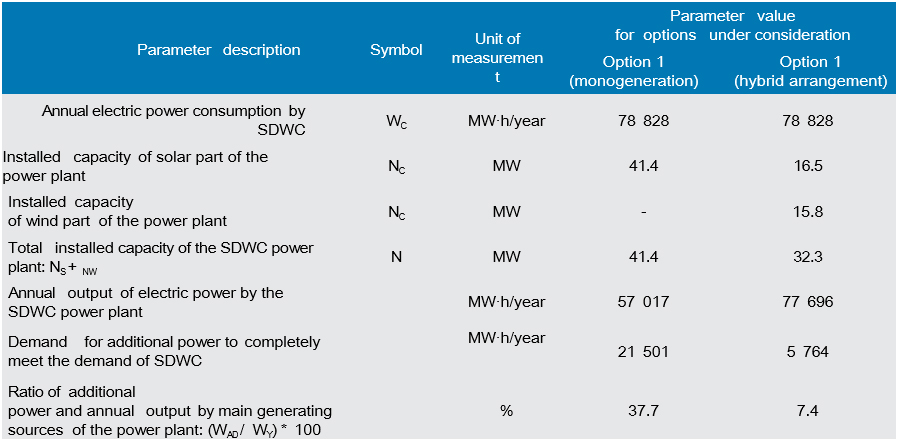

Since Ust-Donetsk area of Rostov region is characterized by good solar and wind energy potential, these types of RES can be used to generate cheap electric power. Two options for the Shakhty-Don Water Conduit power supply were developed:

Option 1 – the use of solar energy with solar power plant design installed capacity of 41.4 MW – with 165.5 thousand photovoltaic modules of FSM-250P type, 250 W each manufactured by SunWays, Moscow;

Option 2 – combined use of solar and wind energy with a sum power plant installed capacity of 32.3 MW (solar part is 16.5 MW – with 66 thousand photovoltaic modules of FSM-250P type, 250 W each, wind part – 15.8 MW – 5 wind power generating units of SWT-3.15–142 type by Siemens (Germany), each with a capacity of 3.15 MW, with a wind turbine diameter of 142 m and a tower height of 165 m).

Results of parameter calculation for the power plants in question are presented in Fig. 2 for option 1 and in Fig. 3 for option 2. In these figures electric power consumption of Shakhty-Don Water Conduit (curves 1) corresponds to actual mean annual values. Electric power output by solar and wind components is calculated by standardized methods [8]. Input climatic actinometric data for the calculations are taken from National Aeronautics and Space Administration of the USA (NASA) for the considered area of Rostov region. The presented calculation results allow making the following conclusions:

Option 1 can provide completely the required power consumption only in the period from April to August when solar radiation input is at its maximum. During other periods considerable energy will be required from additional source (curve 3 in Fig. 2).

Option 2 allows solving this problem with less expenses. Solar energy provide electric power for consumers of Shakhty-Don Water Conduit mainly in summer, while wind energy meets the demand in winter, autumn and spring.

Total generation of solar and wind power change a little during a year (curve 2 in Fig. 3). The demand for electric power from additional source (curve 5 in Fig. 3) in this case appears many times less than in option 1.

Table 2 shows comparison of obtained results.

The option with combined use of RES (option 2) has clear advantages as compared with the option of monogeneration based on solar energy only (option 1). The required installed capacity of electric power plant in option 2 is more than 20% lower than in option 1. This is reflected in the volume of required capital expenses, investment payback period, cost of generated electric power. At the same time, volume of the additional generation to completely meet the demand of the facility for electric power in option 2 is 3.7 times less than in option 1.

This also results in lower required additional investments.

The described advantages allow unambiguously define option 2 as priority, which confirms effectiveness of the proposed method of guaranteed power supply using RES.

To provide additional electric power, the described project makes use of the system of biomass conversion to electric and heat energy proposed by JIHT RAS. Today these system are already well approved [17–21] and leave behind all other methods of additional power generation in terms of financial and commercial efficiency. For the project of Shakhty-Don Water Conduit power plant a system developed by JIHT RAS was adopted to produce high-calorific energy syngas by method of two-stage thermal conversion of wood biomass wastes with further use of the generated gas to fuel gas-reciprocating machines to generate electricity and heat [10, 12, 13]. The project of independent power supply of Shakhty-Don Water Conduit in its final version is based on the use of three types of RES: solar energy, wind energy and biomass energy, and provides guaranteed power supply to consumers of the water conduit without interconnection with the territorial power system and without fossil fuels use.

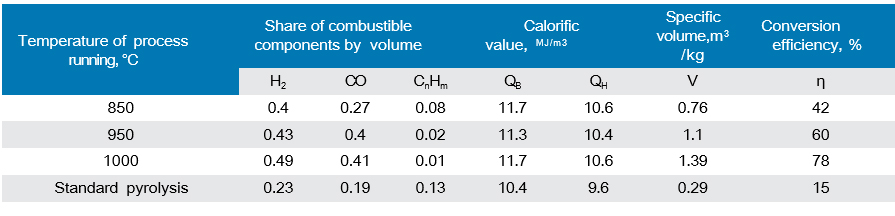

Effective domestic technology of biomass conversion proposed by JIHT RAS allows generating combustible gases by reversed gasification method followed by thermal decomposition of volatile gases with their conversion to syngas practically without resins and ash. This allows using the generated syngas without additional purification as a fuel for gas reciprocating machines. Properties variation of high-calorific energy gases depending on temperature of the biomass conversion process is shown in Table 3.

The main advantage of the technology developed by JIHT RAS is high degree of conversion of the processed biomass to the energy gas. For existing technologies this value is not greater than 25%, while for JIHT RAS technology it achieves 78%. Sum output of combustible gases is 1.4 m3 per 1 kg of biomass, while mean calorific value is about 11.5 MJ/m3.

The described plant for two-stage thermal conversion of wastes to syngas (SGP) is the most effective when processing wood organic wastes, i.e. sawdust, cuttings, chips, bark, crushed wood from timber processing and wood processing wastes, etc. At the same time, effective use of SGP is possible with solid wastes of agricultural processing that contain large quantity of lignin, cellulose, hemicellulose: nuts, hazel, fruit kernels, sunflower/rice seed hulls, grain crops straw, etc., as well as organic part of solid household waste (SHW).

It’s becoming apparent that currently valid Energy Strategy until 2035 [5] and General Layout Plan of Power Facilities until 2035 [6], where future structure of generating capacities is practically kept at the today level – with big share of power generation based of fossil organic fuels and nuclear fuel are already out of the world trends, social/economic and environmental needs of the country and require complete rethink.

The United Nations Climate Change Conference (December 2015, Paris) recommended to limit the use of fossil fuels by 2050 so as to use no more than 10% of available reserves, for the goal of limiting global warming to well below 2 °C by this time.

Within the specified limits about 80% pf world reserves of coal, 50% of natural gas and 30% of oil should be left unused.

Today we need to finance the research activities aimed at creation of new methods of power generation without fossil fuel use. We have no more than 10-15 years to find sources of budget revenues other than export of natural hydrocarbons.

Conclusions

Currently, we need to develop new approaches to ensuring guaranteed power supply to consumers for various purposes. Development of small renewable power sector can be based on creation of the proposed systems with combined use of various RES types and local bioenergy resources supplementing each other and ensuring guaranteed power supply to consumers at minimum required investments.

Systems with the use of RES shall be developed with clearly defined organization and planning of conversion of the entire power industry in Russia, and this development shall be harmonized with goals and objectives of the implementation program of main national projects and growth of the national economy.

References:

- V.M. Zaychenko, A.A. Chernyavsky, Compiling Economic Parameters for Facilities of Traditional and Renewable Power Generation. – Sevastopol: Collection of papers based on proceedings of the International Research-to-Practice Conference «Environmental, Industrial Safety and Security of Energy Supply – 2018», (September 24 – 27, 2018) / L.I. Lukina, N.A. Bezhin, N.V. Lyamina Eds. – Sevastopol: SevSU, 2018. P. 425–428.

- World Nuclear Industry Status Report – 2019.

- Solar Energy Today / Alternative Energy. New York, 2014.

- Traditional Power Industry Will Lose $20 tln. Due To Renewable Energy Sources. – EEnergy Media / Electrovesty.net, July, 2018.

- Draft of Energy Strategy of the RF until 2035. – M.: RF Government Resolution of 09.06.2017 No. 1209-r.

- General Layout Plan of Power Facilities until 2035. – M.: RF Government Resolution of 09.06.2017 No. 1209-r.

- V.M. Batenin, V.M. Zaychenko, A.I. Leontyev, A.A. Chernyavsky, The Concept of Distributed Power Industry Development in Russia. – M.: Bulletin of the Russian Academy of Sciences – Branch of Power Industry 2017, No. 1. P. 3–18.

- V.M. Zaychenko, A.A. Chernyavsky, Stand-alone Power Supply Systems. – M.: NEDRA Publishing House LLC, 2015, 285 p., il. ISBN 978-5-83650458-17.

- V.M. Batenin, A.V. Bessmertny, V.M. Zaychenko et al. Thermal Methods of Wood and Turf Processing for the Purpose of Power Generation. Thermal Power Sector. 2010, No. 11. P. 36–42.

- V.M. Batenin, V.M. Zaychenko, V.F. Kosov, et al. Pyrolytic Conversion of Biomass to Gaseous Fuel. Report of the Academy of Sciences. 2012, V. 446, No.2. P. 179–184.

- Larina O.M., Zaichenko V.M. Energy production from Chicken Manure by Pyrolysis and Torrefaction // Proceedings of the 25th European Biomass Conference and Exhibition EUBCE Stockholm, Sweden. 2017, Р. 1205–1209

- Larina O.M., Sinelshchikov V.A., Sitchev G.A. Comparison of Thermal Conversion Methods of Different Biomass Types into Gaseous Fuel // Journal of Physics Conference Series. 2016, volume 774/012137.

- L.B. Director, V.M. Zaychenko, R.L. Isyemin, A.A. Chernyavsky, A.L. Shebchenko, Efficiency Comparison of Low-temperature Biomass Pyrolysis Reactors // Thermal power sector. 2020, No. 5. P. 60–69.

- Patent RF No. 2359007 – Method of Receiving of Hydrocarbon Fuel, Technological Hydrogen and Carbon-Base Materials from Biomass. 2008

- Patent RF No. 2378319 – Method of Receiving of Hydrocarbon Fuel and Carbon-Base Materials from Biomass. 2008

- Patent RF No. 2380395 – Method of Pyrolysis Processing of Bio-Mass 2010.

- Patent RF No. 2698829 – Pypolysis Thermal Gas-Chemical Plant for Utilisation of Solid Domestic Waste. 2019.

- Patent RF No. 136799 – Energy Technical System for Multifunctional Conversion of Biomass. 2013.

- Patent RF No. 136801 – Power Generating System with Biomass Torrefier. 2013.

- Patent RF No. 161775 – Granulated Biomass Torrefier. 2016

- Patent RF No. 169133 – Torrefaction Reactor. 2017.